Course Features

Price

Study Method

Online | Self-paced

Course Format

Reading Material - PDF, article

Duration

15 minutes

Qualification

No formal qualification

Certificate

At completion

Additional info

Coming soon

- Share

Overview

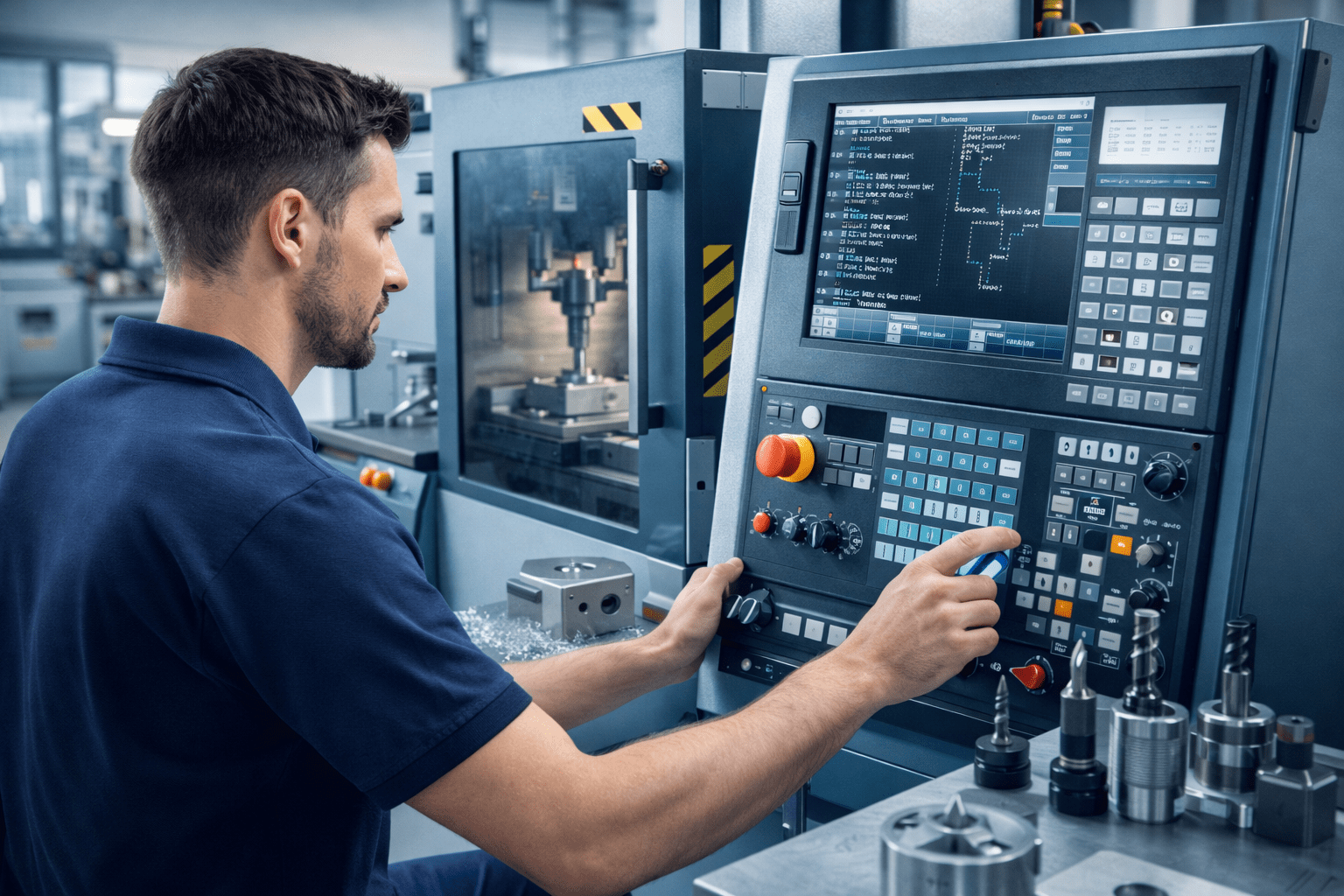

CNC milling programming is a critical skill for anyone who wants to work confidently with modern manufacturing equipment, and this masterclass is designed to take you from foundational concepts to advanced machine control using professional G-code. The course introduces how CNC milling machines operate, how tools and cutting conditions are selected, and how precise movements are programmed to produce accurate, repeatable components.

Learners will build a strong understanding of how digital instructions are converted into real-world machining actions. You will explore coordinate systems, feed rates, spindle speeds, and tool offsets so that you can control every stage of the cutting process with precision. As you progress, you will gain the ability to write, read, and interpret G-code used to drive milling machines in industrial workshops, engineering firms, and manufacturing plants.

This programme also develops practical problem-solving skills. You will learn how to choose appropriate tools, apply cutting fluids correctly, and adjust machining parameters to improve surface finish, reduce wear, and prevent costly mistakes. By working through a structured progression from simple positioning commands to advanced drilling and contouring cycles, you gain the confidence to handle a wide range of milling tasks safely and efficiently.

In addition to technical ability, the course supports professional development. Understanding machine safety, operational logic, and programming standards allows you to communicate effectively with engineers, supervisors, and production teams. These competencies are highly valued in CNC-based workplaces where accuracy, efficiency, and reliability are essential.

By the end of the masterclass, learners can plan machining operations, create structured programs, and troubleshoot errors with clarity and confidence. These skills help you move from being a machine operator to a knowledgeable CNC programmer capable of supporting complex manufacturing projects.

All learners receive a free course completion certificate when they finish the programme. Multiple premium certificate and transcript options are also available for purchase for those who wish to enhance their professional profile. Students also benefit from 5-star rated support available 24/7 via email, ensuring expert help is always within reach.

Who is this course for?

CNC milling programming is a critical skill for anyone who wants to work confidently with modern manufacturing equipment, and this masterclass is designed to take you from foundational concepts to advanced machine control using professional G-code. The course introduces how CNC milling machines operate, how tools and cutting conditions are selected, and how precise movements are programmed to produce accurate, repeatable components.

Learners will build a strong understanding of how digital instructions are converted into real-world machining actions. You will explore coordinate systems, feed rates, spindle speeds, and tool offsets so that you can control every stage of the cutting process with precision. As you progress, you will gain the ability to write, read, and interpret G-code used to drive milling machines in industrial workshops, engineering firms, and manufacturing plants.

This programme also develops practical problem-solving skills. You will learn how to choose appropriate tools, apply cutting fluids correctly, and adjust machining parameters to improve surface finish, reduce wear, and prevent costly mistakes. By working through a structured progression from simple positioning commands to advanced drilling and contouring cycles, you gain the confidence to handle a wide range of milling tasks safely and efficiently.

In addition to technical ability, the course supports professional development. Understanding machine safety, operational logic, and programming standards allows you to communicate effectively with engineers, supervisors, and production teams. These competencies are highly valued in CNC-based workplaces where accuracy, efficiency, and reliability are essential.

By the end of the masterclass, learners can plan machining operations, create structured programs, and troubleshoot errors with clarity and confidence. These skills help you move from being a machine operator to a knowledgeable CNC programmer capable of supporting complex manufacturing projects.

All learners receive a free course completion certificate when they finish the programme. Multiple premium certificate and transcript options are also available for purchase for those who wish to enhance their professional profile. Students also benefit from 5-star rated support available 24/7 via email, ensuring expert help is always within reach.

Requirements

CNC milling programming is a critical skill for anyone who wants to work confidently with modern manufacturing equipment, and this masterclass is designed to take you from foundational concepts to advanced machine control using professional G-code. The course introduces how CNC milling machines operate, how tools and cutting conditions are selected, and how precise movements are programmed to produce accurate, repeatable components.

Learners will build a strong understanding of how digital instructions are converted into real-world machining actions. You will explore coordinate systems, feed rates, spindle speeds, and tool offsets so that you can control every stage of the cutting process with precision. As you progress, you will gain the ability to write, read, and interpret G-code used to drive milling machines in industrial workshops, engineering firms, and manufacturing plants.

This programme also develops practical problem-solving skills. You will learn how to choose appropriate tools, apply cutting fluids correctly, and adjust machining parameters to improve surface finish, reduce wear, and prevent costly mistakes. By working through a structured progression from simple positioning commands to advanced drilling and contouring cycles, you gain the confidence to handle a wide range of milling tasks safely and efficiently.

In addition to technical ability, the course supports professional development. Understanding machine safety, operational logic, and programming standards allows you to communicate effectively with engineers, supervisors, and production teams. These competencies are highly valued in CNC-based workplaces where accuracy, efficiency, and reliability are essential.

By the end of the masterclass, learners can plan machining operations, create structured programs, and troubleshoot errors with clarity and confidence. These skills help you move from being a machine operator to a knowledgeable CNC programmer capable of supporting complex manufacturing projects.

All learners receive a free course completion certificate when they finish the programme. Multiple premium certificate and transcript options are also available for purchase for those who wish to enhance their professional profile. Students also benefit from 5-star rated support available 24/7 via email, ensuring expert help is always within reach.

Career path

CNC milling programming is a critical skill for anyone who wants to work confidently with modern manufacturing equipment, and this masterclass is designed to take you from foundational concepts to advanced machine control using professional G-code. The course introduces how CNC milling machines operate, how tools and cutting conditions are selected, and how precise movements are programmed to produce accurate, repeatable components.

Learners will build a strong understanding of how digital instructions are converted into real-world machining actions. You will explore coordinate systems, feed rates, spindle speeds, and tool offsets so that you can control every stage of the cutting process with precision. As you progress, you will gain the ability to write, read, and interpret G-code used to drive milling machines in industrial workshops, engineering firms, and manufacturing plants.

This programme also develops practical problem-solving skills. You will learn how to choose appropriate tools, apply cutting fluids correctly, and adjust machining parameters to improve surface finish, reduce wear, and prevent costly mistakes. By working through a structured progression from simple positioning commands to advanced drilling and contouring cycles, you gain the confidence to handle a wide range of milling tasks safely and efficiently.

In addition to technical ability, the course supports professional development. Understanding machine safety, operational logic, and programming standards allows you to communicate effectively with engineers, supervisors, and production teams. These competencies are highly valued in CNC-based workplaces where accuracy, efficiency, and reliability are essential.

By the end of the masterclass, learners can plan machining operations, create structured programs, and troubleshoot errors with clarity and confidence. These skills help you move from being a machine operator to a knowledgeable CNC programmer capable of supporting complex manufacturing projects.

All learners receive a free course completion certificate when they finish the programme. Multiple premium certificate and transcript options are also available for purchase for those who wish to enhance their professional profile. Students also benefit from 5-star rated support available 24/7 via email, ensuring expert help is always within reach.

-

-

- Premium Certificate 00:15:00

No Reviews found for this course.

Is this certificate recognized?

Yes, our premium certificate and transcript are widely recognized and accepted by embassies worldwide, particularly by the UK embassy. This adds credibility to your qualification and enhances its value for professional and academic purposes.

I am a beginner. Is this course suitable for me?

Yes, this course is designed for learners of all levels, including beginners. The content is structured to provide step-by-step guidance, ensuring that even those with no prior experience can follow along and gain valuable knowledge.

I am a professional. Is this course suitable for me?

Yes, professionals will also benefit from this course. It covers advanced concepts, practical applications, and industry insights that can help enhance existing skills and knowledge. Whether you are looking to refine your expertise or expand your qualifications, this course provides valuable learning.

Does this course have an expiry date?

No, you have lifetime access to the course. Once enrolled, you can revisit the materials at any time as long as the course remains available. Additionally, we regularly update our content to ensure it stays relevant and up to date.

How do I claim my free certificate?

I trust you’re in good health. Your free certificate can be located in the Achievement section. The option to purchase a CPD certificate is available but entirely optional, and you may choose to skip it. Please be aware that it’s crucial to click the “Complete” button to ensure the certificate is generated, as this process is entirely automated.

Does this course have assessments and assignments?

Yes, the course includes both assessments and assignments. Your final marks will be determined by a combination of 20% from assignments and 80% from assessments. These evaluations are designed to test your understanding and ensure you have grasped the key concepts effectively.

Is this course accredited?

We are a recognized course provider with CPD, UKRLP, and AOHT membership. The logos of these accreditation bodies will be featured on your premium certificate and transcript, ensuring credibility and professional recognition.

Will I receive a certificate upon completion?

Yes, you will receive a free digital certificate automatically once you complete the course. If you would like a premium CPD-accredited certificate, either in digital or physical format, you can upgrade for a small fee.

Course Features

Price

Study Method

Online | Self-paced

Course Format

Reading Material - PDF, article

Duration

15 minutes

Qualification

No formal qualification

Certificate

At completion

Additional info

Coming soon

- Share

Oceanography and Coastal Management Level 3 Advanced Diploma

Course Line237$913.69Original price was: $913.69.$27.95Current price is: $27.95.Fundamentals of Draughtsmanship

Course Line238$913.69Original price was: $913.69.$27.95Current price is: $27.95.ABRSM Aural Skills Development: Listening, Singing & Musical Memory

Course Line237$913.69Original price was: $913.69.$27.95Current price is: $27.95.

Related Courses

Civil Engineering Building Construction Fundamentals: Site, Codes & Quantity Skills

$913.69Original price was: $913.69.$27.95Current price is: $27.95. 237

237Mechanical Engineering Level 7 Advanced Diploma

$913.69Original price was: $913.69.$27.95Current price is: $27.95. 237

237Digital Electronics Fundamentals: Logic Gates & Boolean Algebra Explained

$913.69Original price was: $913.69.$27.95Current price is: $27.95. 237

237

Related Courses

Civil Engineering Building Construction Fundamentals: Site, Codes & Quantity Skills

$913.69Original price was: $913.69.$27.95Current price is: $27.95. 237

237Mechanical Engineering Level 7 Advanced Diploma

$913.69Original price was: $913.69.$27.95Current price is: $27.95. 237

237Digital Electronics Fundamentals: Logic Gates & Boolean Algebra Explained

$913.69Original price was: $913.69.$27.95Current price is: $27.95. 237

237